WALL FIRED BURNER

- The LJE&EC burner is an advanced solution for low NOx oil/gas firing applications, without adversely affecting boiler performance.

- This low NOX burner was developed to achieve superior NOX performance with more than 20 years of experience, assuring desired results.

- LJE&EC developed the burner with a focus on maximum NOX reduction with optimum combustion efficiency, safety, and easy operation.

- The compact design makes it well suited for retrofit applications and the burner requires minimal maintenance.

- Each burner is completely shop assembled and mechanically tested before delivery.

- The burner is designed as a retrofit, with little or no modifications on the boiler.

CCE&CE’S LOW NOX BURNER:

- Proven performance in NOx reduction.

- High flame stability and burner turndown.

- Lower CO emissions / Excess air.

- Adjustable of vanes to optimize performance

- High heat resistance steel is used in all parts of the burner exposed to radiant furnace heat.

WIDE RANGE OF FUELS

- Natural gas

- Refinery fuel gas

- Vaporized naphtha or 100% hydrogen

- Optional waste gas firing

- Heavy Oils – Low Sulfur Heavy Stock (LSHS), Furnace Oil (FO), Tar.

- Light Oils – Naphtha, Natural Gas Liquid (NGL), Light Diesel Oil (LDO), High-Speed Diesel (HSD), Kerosene, C-9, and their likes.

Heat Release:

Burner can be designed for any heat release rate/throat size.

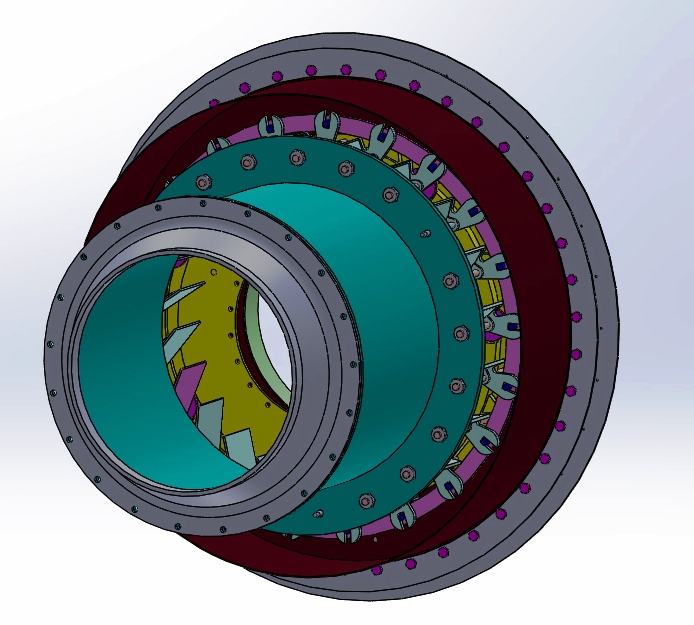

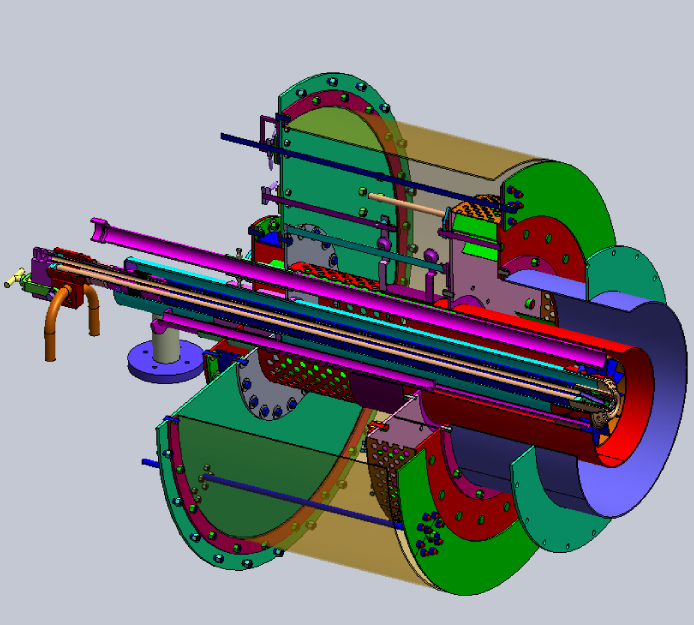

Air register:

Optimized air distribution improves the flame shape and emission performance, excess air control.

Low maintenance:

- Robust refractory throat for increased life.

- Centrally placed and easily removable gas burner.

Reliability and Efficiency:

- Compact flames minimize flame impingement.

- No metal in the throat, only refractory.

- In high stability over a wide range of fuels and operating conditions

- Oil gun – Produces a finer oil spray with Y-jet type of tips, minimizes atomizer plugging.

- Damper actuator – Easily adjusts the main air damper position for light-off, full-load, and out-of-service cooling.

- Primary air damper – Adjusts primary airflow to the oil gun or gas spuds for optimizing combustion.

- Secondary air damper – Adjusts the secondary airflow to shape the flame and distribute the air.

- Spinner vanes – Provide proper mixing of the secondary air and fuel – vane.