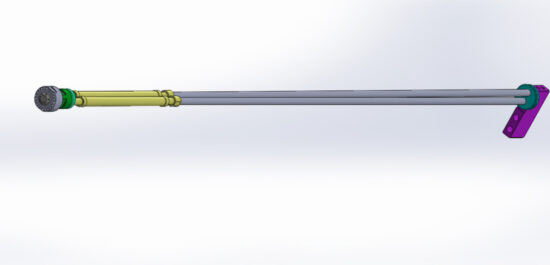

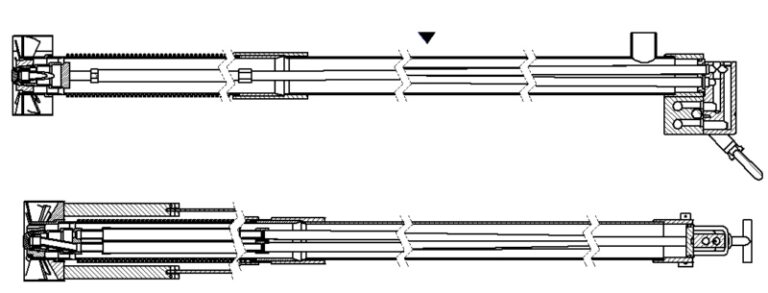

Air Cooled Oil Gun

Air-cooled oil guns are developed to replace the high maintenance cost and cumbersome retract mechanism.

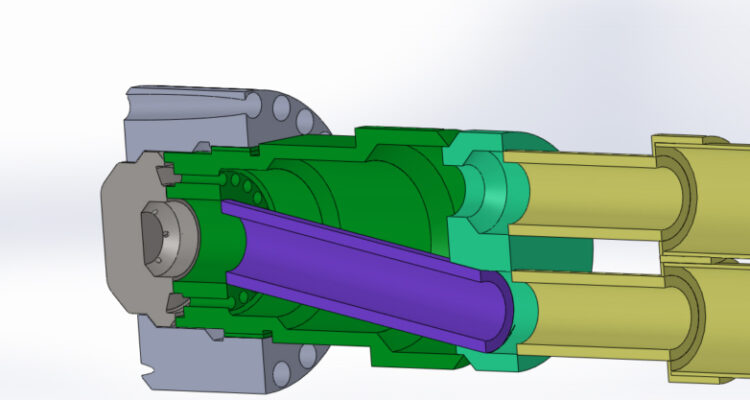

PRINCIPLE

The air-cooled oil gun is cooled by a low-pressure stream of air passing through a specially designed gun cap with a finned surface.

The low-pressure air passing around the atomizer shields and reduce the furnace radiation falling on the atomizer parts by extracting heat through the finned surfaces.

COOLING AIR REQUIREMENT

Standard Capacity Guns 2 – 2.5 sm3/min of ambient air at 50 – 60mm WC above furnace pressure

High Capacity Guns 4 – 4.5 sm3/min of ambient air at 80 – 100 mm WC. above furnace pressure

POTENTIAL BENEFITS

- Air-cooled oil gun tips are subjected to lower temperatures than retractable oil gun tips. Oil guns remain cool and component life is increased

- Minimizes the congestion at burner elevation. Increases accessibility to the burner front area

- Reduces the maintenance

- Eliminates the number of working components / Complicated Retract mechanism

- More economical than steam or compressed air cooling as the power requirements for low-pressure cooling air is minimal.

- Increase in the life of the tip.

- Can be retrofitted with old boilers easily without any major modification.

- Eliminates “gun advanced’ and “gun retracted” limit switches

- Simplifies control system