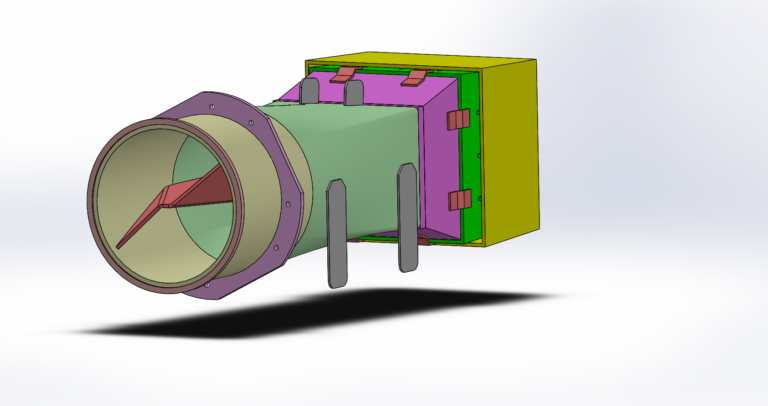

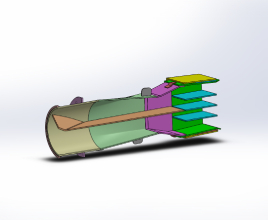

COAL BURNERS / COAL COMPARTMENT ASSY.

- LJES manufacture Coal nozzle, Coal nozzle tips, and complete Coal Compartment assemblies for different sizes of fossil fuel-fired boilers.

- LJES Parts are considered superior due to higher reliability and high fuel load flexibility

- compartment assembly includes the stationary Coal Nozzle and tilting Nozzle Tip and seal plate

- Our Parts are manufactured from super high heat-resistant alloys to ensure longer life.

- The Coal nozzles are either of fabricated design or precision machined.

- Standard coal nozzle of cast ductile iron / ceramic-lined

- Coal Nozzle Tips manufactured from SS-310 plates are susceptible to high wear and severe damage, as this is expected to perform under extreme conditions.

HARDFACING or CERAMIC LINING OPTIONS FOR COAL NOZZLE TIPS

- Hard facing or Ceramic lining is a process of depositing hard matrix to protect high wear areas of splitter plates and leading edges.

- Hard-facing thickness can be 3mm / 6mm.